S2 Integrators’ IoT Consultants have delivered industrial, enterprise, and automotive predictive maintenance solutions for customers across the globe

Predictive services leverage cloud technologies to manage critical asset performance and ensure safety:

• Condition-based maintenance and predictive analytics

• Dedicated experts

The business benefits that can be derived from our IoT predictive maintenance solutions include:

- Higher Asset Availability

- Improved Work-force Productivity

- Optimized Energy Consumption

- Lower operational costs

- A Fool-proof Industrial Asset Management solution at your disposal

Development Services for Cloud-Based Predictive Maintenance Solutions

Our Predictive Monitoring and Analytics are custom-designed for Asset Management, based on your unique business requirements. All our PdM solutions are designed based on the Internet of Things (IoT) Technology Stack.

Listed below are our services pertaining to IoT Predictive Maintenance to help our partners achieve a winning RoI:

- We assist in 24/7 predictive monitoring of your field-deployed industrial and enterprise assets with the help of a well-designed network of IoT sensors. This ensures reduced reaction time to faults and instances of unplanned downtimes.

- Based on your Enterprise Asset Management requirements, the monitoring activities and collection of data can be configured as time-based or trigger-based (occurs when a specific event takes place).

- We help in Dataset preparation by refining the collected data. This data filtering ensures that only the relevant set of enterprise data is used for further processing.

- With integrated advanced Artificial Intelligence(AI) data analytics tools, enable your Industrial Asset maintenance and support teams to make more accurate and intelligent decisions.

- These AI tools are used to gain insights from volumes of IoT sensor data, which are crucial to make critical Predictive Maintenance (PdM) decisions.

- An occurrence of defect or failure may not be a one-day event. This might have been caused due to changes in operating conditions or state of an industrial asset over a period of time.

- Our Predictive Monitoring solutions use historic data including error logs, failed as well as successful outcomes, warnings associated with an industrial equipment – as data records.

- Our Predictive Maintenance (PdM) solution analyses & processes these data records leveraging Machine Learning (ML) techniques. This helps in detecting any anomalous equipment behaviour and thereby predicting its possible failure based on data insights.

Manufacturing Execution Systems (MES)

Advanced manufacturing requires the proper planning of resources, quality management, effective use of tools on the shop floor, management of equipment and human schedules, and quick responses to interruptions and unplanned events. Enterprise Resource Planning systems (ERPs) are specifically designed to manage company-wide resources, scheduling, and supply chain requirements and interruptions. Most advanced manufacturing environments either employ – or use to some degree – ERP systems to orchestrate the many moving parts in order to compete on a global scale.

With an MES in place, KPIs, performance data, and future intelligent planning begin to become available. Cycle time (the time between steps), critical ratio (the measurement of how far a lot is ahead of or behind schedule), equipment metrics pursuant to SEMI-E10 standards, OEE, and a host of other indicators may be available within the MES or – at the very least – the data is available for query and extraction into business intelligence software. The MES makes it possible to collect, control, store, and report this information. To that end, the MES is best-positioned as a “first step” action in any factory’s digital transformation. The MES will grow in scope and complexity as a factory’s systems and automated processes mature and will serve as the foundation for almost every other step in the digital transformation journey.

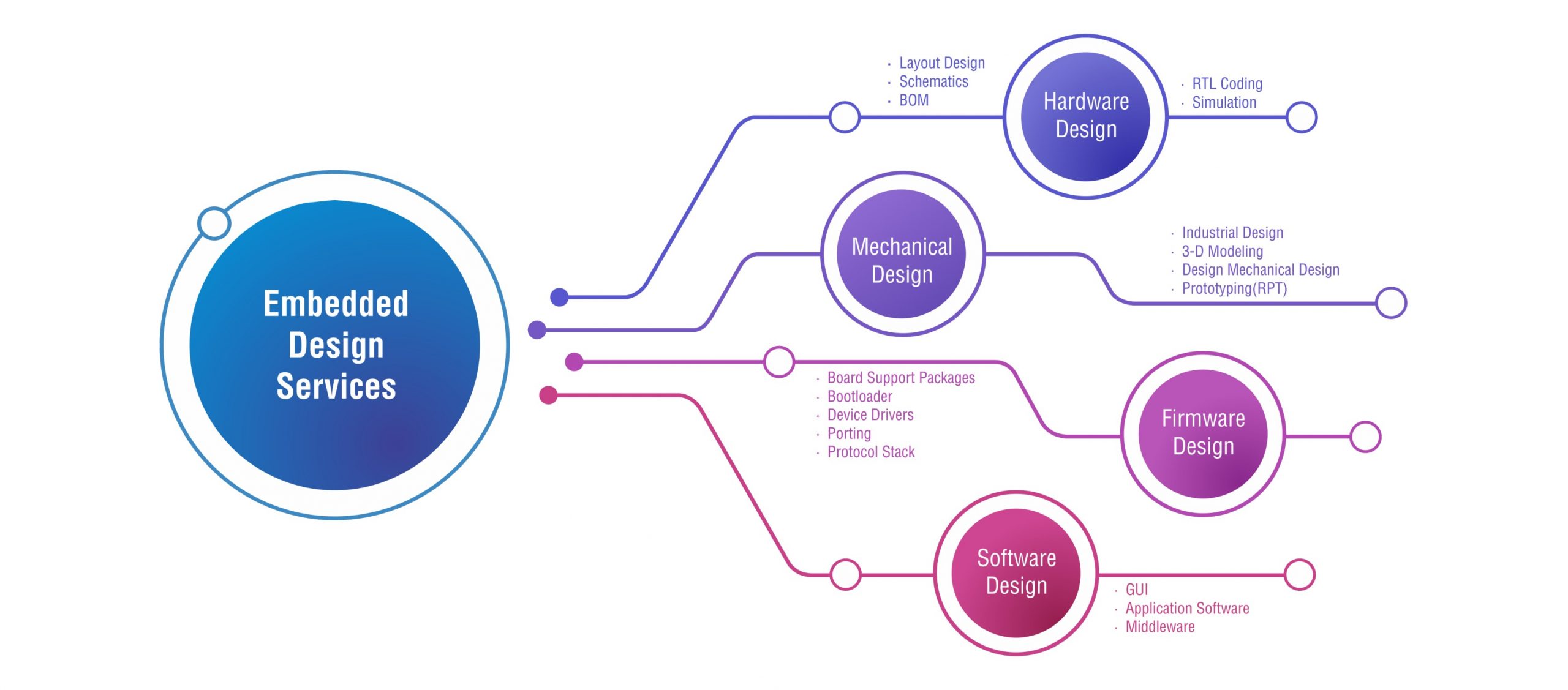

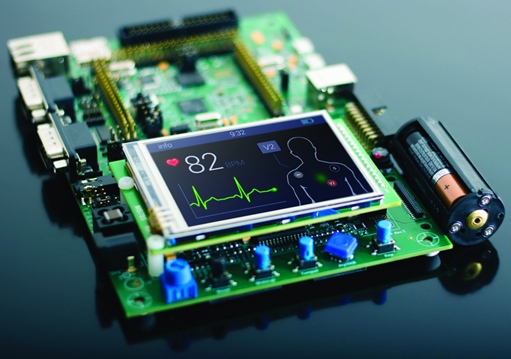

Hardware Design Services

Embedded Design Service team supports complete electronic hardware design activities which include schematic design, bill of material finalization, Printed Circuit Board (PCB) design, prototyping, production support and FPGA design services for customer-specific requirements. The key hardware design ranges from small-footprint, power-optimized solutions to high-end, rugged systems built around various embedded processors and DSPs.

Embedded Firmware / Software Services

DST offers a broad range of software services relating to embedded systems programming and real time embedded systems software development. such as: Boot loader, Development of Board Support Packages, Device Drivers, Firmware and Diagnostics, Yocto Linux, Embedded Linux, WinCE, GUI development, OS porting, Embedded application development Feature enhancements, Development and porting of protocol Stack and Development of Wireless stack.

Embedded Firmware / Software Services

Today, many of the High speed and complex designs need the integration and flexibility that an FPGA can offer. The ability to be reconfigured enables the FPGAs to extend the lifecycle of a custom product to suit the changing market needs. DST has the right experience and capability to satisfy any phase of product life cycle including partial or complete architecture design, feature additions to existing designs, test bench development or functional verification.

FPGA Design Services

DST addresses mechanical design requirement for product engineering with 3D modeling and rapid prototyping techniques to provide early user experience during product development cycle. It also has expertise in re-engineering and tear down analysis for product life extension. With its eco partner, DST provides manufacturing and support to complete mechanical engineering requirements for New Product Development . With its expertise in tools and customized processes, DST brings reliable, feature-rich products at competitive prices with the least development lead time.